- Mobile:

- +86 13625872111

- Tel:

- 0577-59886565

- Email:

- admin@bcmachinery.cn

- Add:

- #358 Weier Road Nanbin Street Ruian City Zhejiang China

Ⅰ、Functional Overview

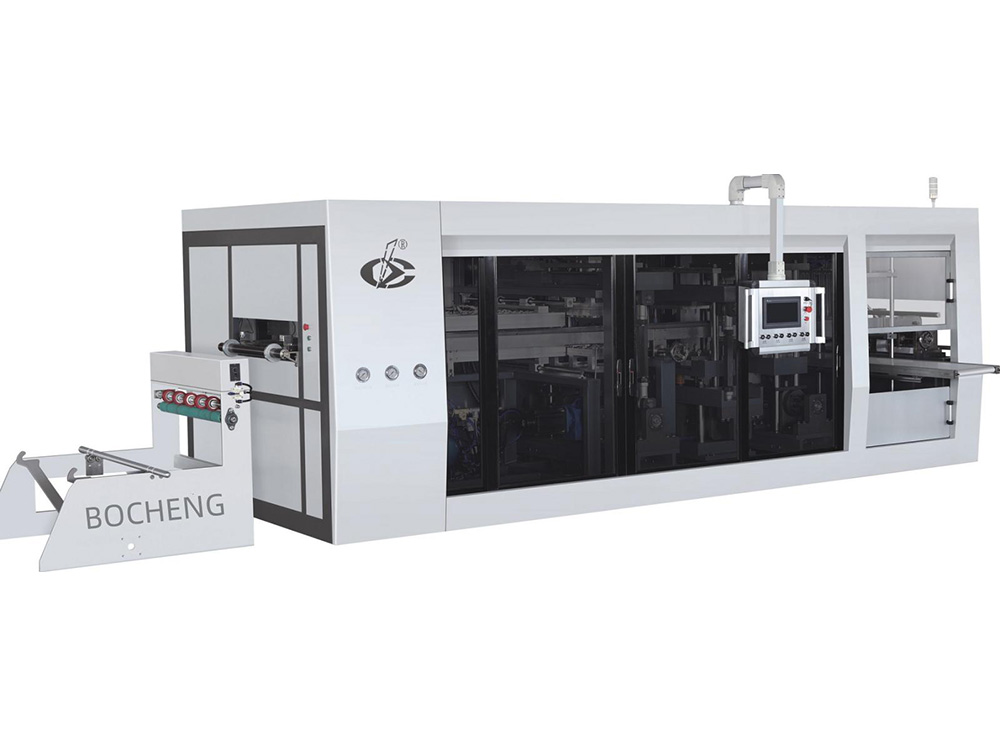

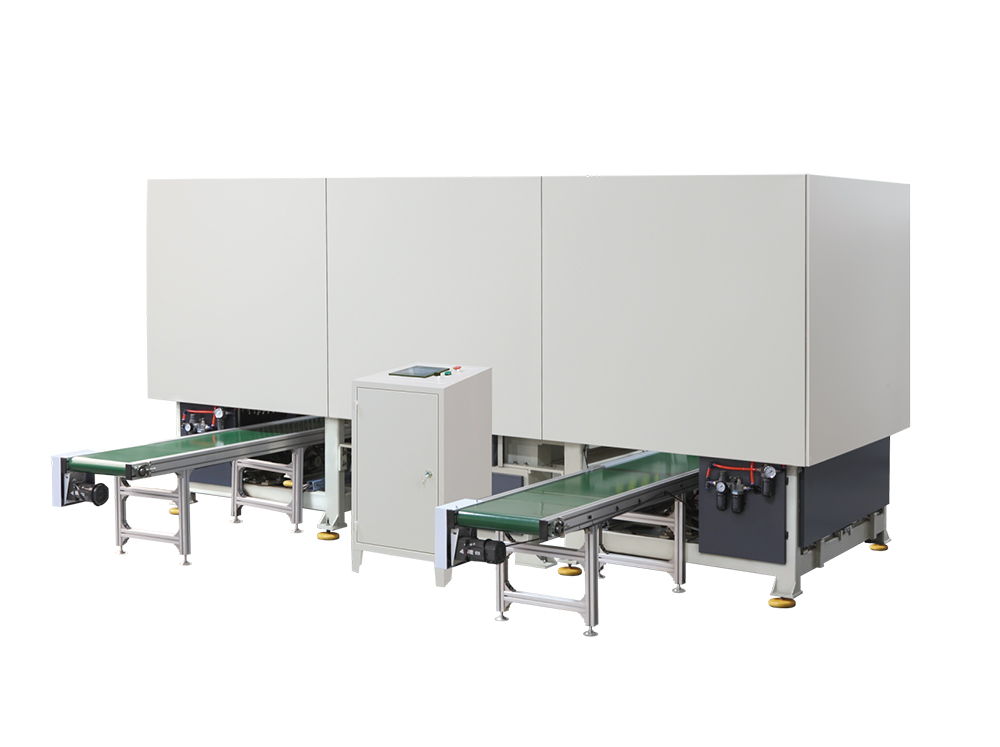

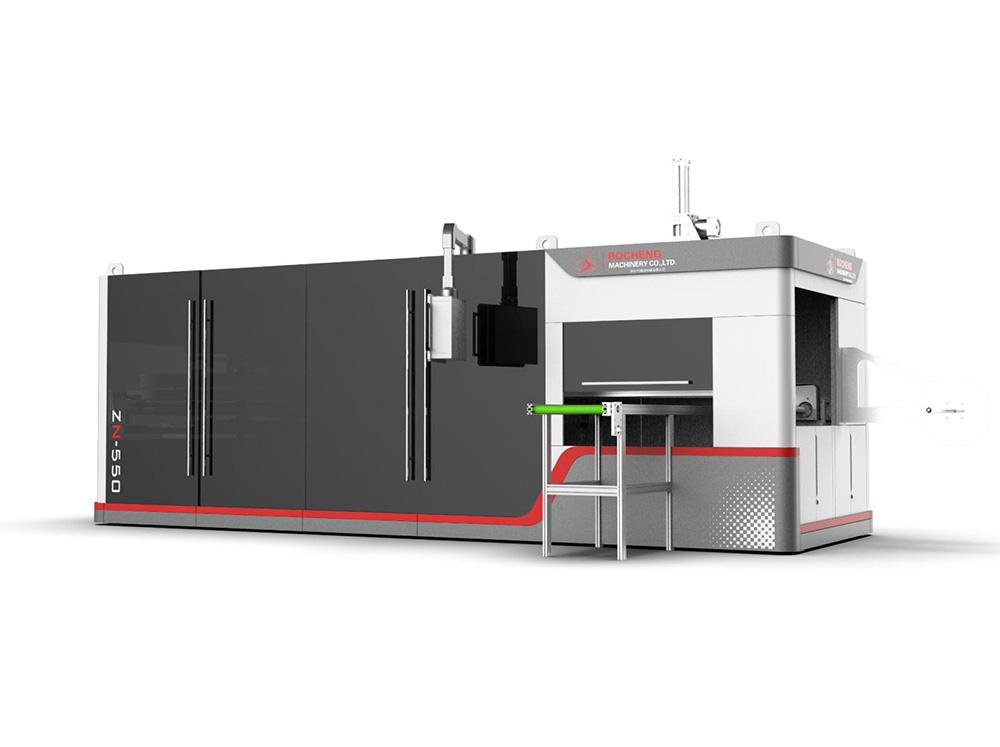

As the first domestic new-type machine, ZN550 automatic positive and negative thermoforming machine, is researched and developed by our scientific researcher according to the market demands and our past production technology. This machine is a multi station automatic machine, solving the problems of food packaging hygienc standards. It not only works effectively in the production of PP, PS, PET, PVC and PLA plastic products, such as reducing capital investment, large labor input, complicated production process, lower hygienic security, etc, but also has extensive usage. It can be used in the production of PP, PS, PET, PVC, PLA plastic products using in metals, food, pharmaceutical, etc. All in all, this automatic positive and negative plastic containers making machine enjoys beautiful appearance and good price. It is popular with the customers at home and abroad.

Ⅱ、Technical Parameters

Description | ZN550 |

Suitable Products | Disposable Plastic lids/covers, clamshell boxes, plates, (egg) trays , containers, etc. |

Suitable Material | PP, PS, PET,PLA, PVC, EPS |

Max. Width of Material | 580mm |

Max. Forming Width | 550mm |

Max. Forming Length | 350mm |

Max. Forming Depth | 80mm |

Max. Cutting Speed | 10-25 Cycles/min |

Material Thickness | 0.1mm-1.2mm |

Main Power | 49KW |

Power | 380V/ 50HZ (Three-phase and four-wire) |

Pressure of Water Supply | 0.2MPa |

Water Consumption | 0.3m3/h (Tap water or Circulating cooling water) |

Air Exhaust Volume | ≥0.8m3/min |

Air Pressure | 0.6-0.8MPa |

Machine Install Size | 6000×1800×2100mm |

Machine Packing Size | 6200×2000×2300mm |

Weight | 5500KG |

Remark:

Due to technical improvements, the manufacturer reserves the right to modify the above parameters and functions without prior notice.

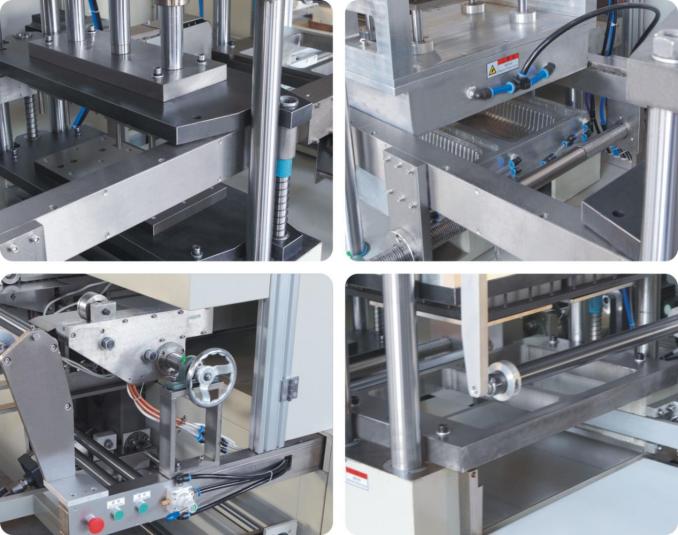

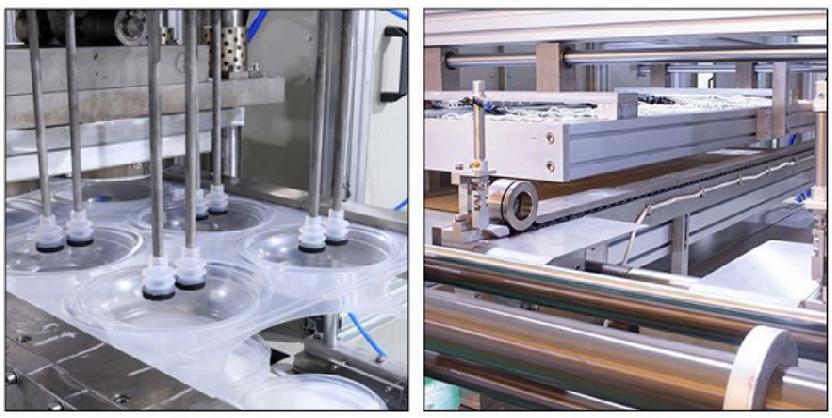

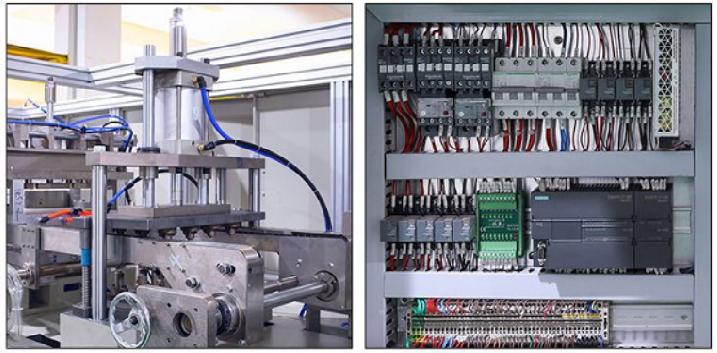

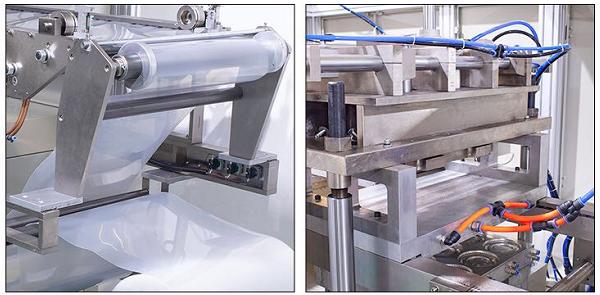

Ⅲ、Machine Detailed Picture

This Machine has Forming, Punching, Cutting and Stacking stations which are driven by servo motor independently to ensure high efficiency and stability of production. The forming station used Lengthening upper and lower heating system and positive & negative pressure molding device to ensure that difficult materials and temperature resistant materials are heated evenly. The qualified rate of finished products reached 99.9%. The mold is made of 6061 aluminum alloy and laser knife which improves the punching accuracy (error within ±0.2mm). It not only reduces the cost of mold making, shortens the mold making cycle but also facilitates the replacement of molds.

Ⅳ、Machine Configuration List

NAME | BRAND |

Touch Screen | INOVANCE |

PLC | INOVANCE |

Encoder | Korea |

Relay | Schneider France |

Proximity switch | Schneider France |

power switch | Schneider France |

Servo Motor | INOVANCE |

Temperature module | Hexin China |

Circuit breaker | Schneider France |

Button switch | Schneider France |

Emergency stop switch | Schneider France |

Solenoid valve | AIRTAC Taiwan |

Cylinder | AIRTAC Taiwan |

Solid state relay | Yangming Taiwan |

Reducer | Tongli China |

Pressure reducing valve | AIRTAC Taiwan |

Ⅴ、Special note

Due to technical improvements, the manufacturer reserves the right to modify the above parameters and functions without prior notice.

Packing | First wrapped by film, then in export wooden boxes, then in container. |

Payment Term | T/T, 30% pay in advance, the balance should pay before delivery. |

Delivery Time | 45 Working days after deposit and drawing confirmed. |

Installation |

The seller will for certain dispatch the technician to your country for installation, commissioning, adjusting the machine and training the workers in your plant. However the buyer should take on all costs required during our technician's stay in the buyer's country, round airplane tickets, accommodation, foods. The technician’s salary will be paid by us within a week. If more than a week, the technician's salary will be paid by customers. It takes customers 120USD/Day.

|

Guaranty Terms

|

We seller guarantee the machines are new (or unused) and the guarantee period will be given twelve months which starts from the date of the machine's arrival. During this period, the seller will provide free maintenance and free spare parts that caused by the machine's quality, but the buyer must pay the round trip tickets and accommodation expenses for seller's technicians. |

Ⅵ、Sample picture