- Mobile:

- +86 13625872111

- Tel:

- 0577-59886565

- Email:

- admin@bcmachinery.cn

- Add:

- #358 Weier Road Nanbin Street Ruian City Zhejiang China

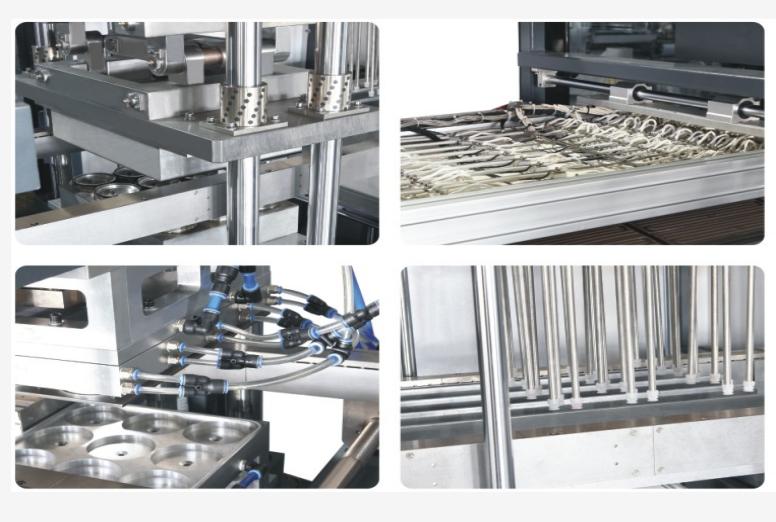

Ⅰ、Machine Detailed Picture

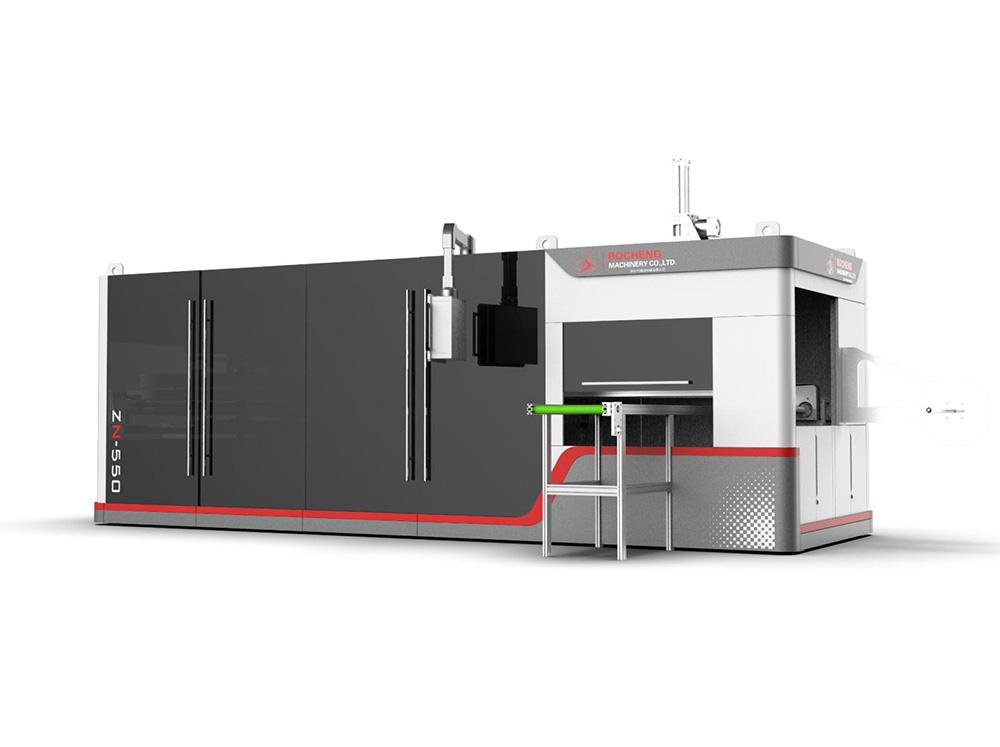

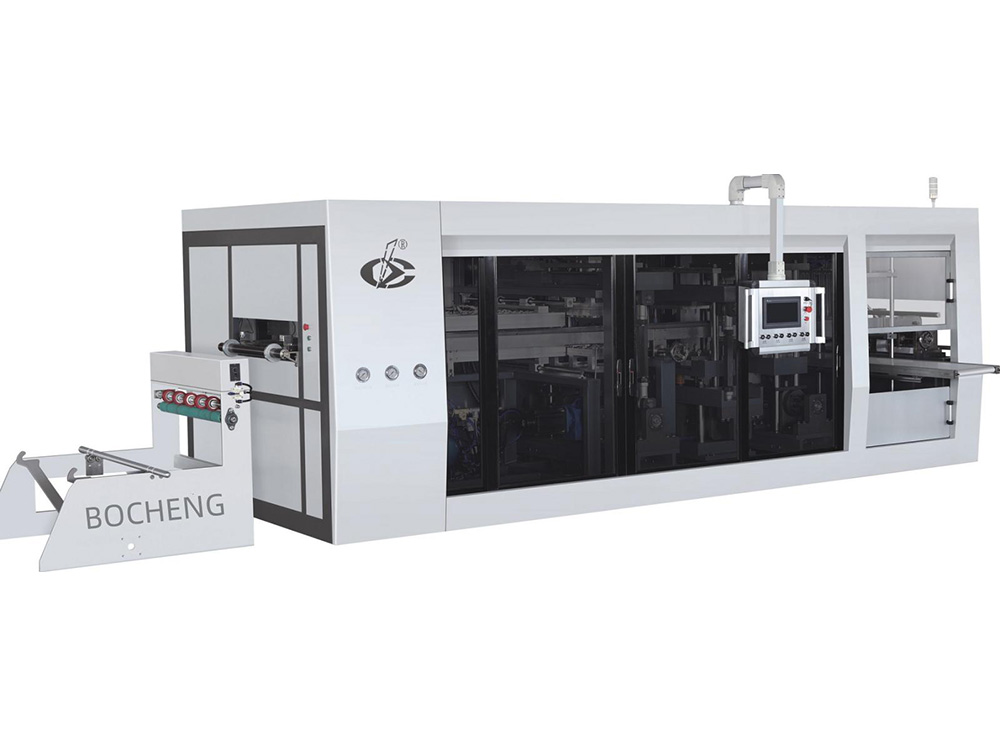

Real Machine Overview

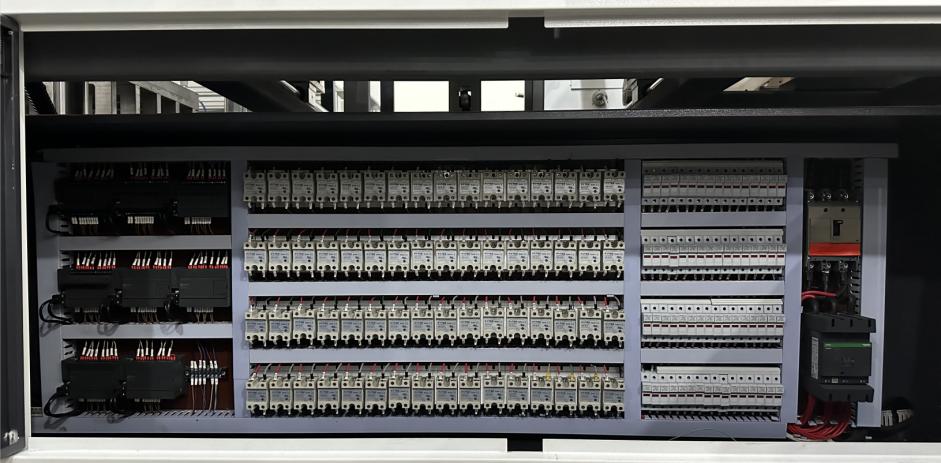

Electrical box

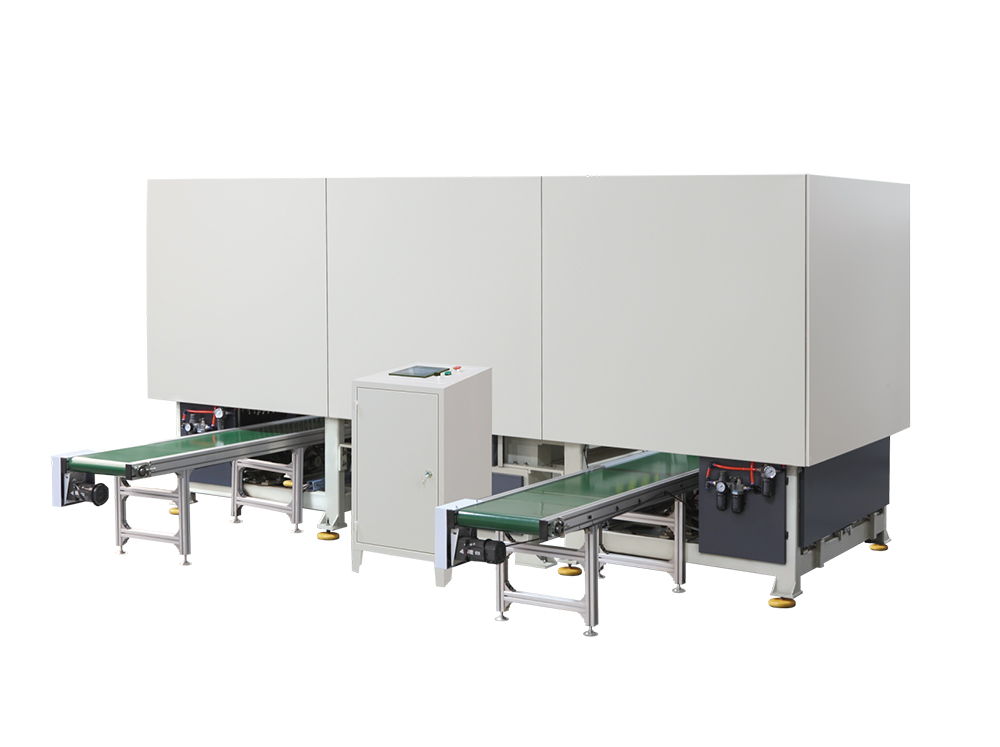

Four Station & Heating

Ⅱ、Function Brief Introduction

1, Control system: Through the combination of motion control module, 3D industrial touch screen, servo motor, photoelectric, temperature control and other intelligent control system, the operation is simple and intuitive,our pursuit is any basic level worker can run the machine with instruction.

2, Traction: High power servo traction feeding device ensures the traction length of sheet (thickness 0.1mm-1.5mm) with accuracy.

3, Structure: Forming, Punching, Cutting and Stacking are driven by well known servo motor. Each station is able to operate independently, imported five-axis processing equipment ensure high efficiency and stability of production.

4, Forming: Using the ultra-long upper and lower heating box of far-infrared ceramic heating brick, intelligent temperature control, positive and negative pressure forming structure, to ensure that difficult materials, temperature resistant materials are heated evenly, so that the product thickness is uniform, beautiful appearance, so as to enhance the market competitiveness

5, Mold: Aluminum alloy (imported air permeable aluminum) forming mold made by CNC fine engraving and milling, positive and negative pressure, water circulation structure, speed up the molding, cooling speed; The die punching is made by hardware knife or laser knife (depending on the product); The die punching is made of laser cutter movable structure, which has the advantages of improving the punching accuracy (error within ±0.2mm), reduces mold cost, shortens mold production time, and makes mold change easily.

6, Whole machine: The frame is welded with steel box body combine with Welding, Molding, Punching and Cutting four station, with strong structure and no deformation. Both the bracket and box body are pressurized, with high density. The shape is designed with sliding door, beautiful appearance and easy to maintain.

Ⅲ、Cooperate Friend Country

Now our machines have been widely used in many countries, such as Germany, France, Albania, Poland, Macedonia, Chile, Argentina, Ecuador, Middle East, Middle Asia, Southeast Asia, Africa and etc

Remark: Due to technical improvements, the manufacturer reserves the right to modify the above parameters and functions without prior notice.

Ⅳ、Technical Parameters

Description | ZN-650 |

Suitable Products | Disposable Plastic lids/covers, clamshell boxes, plates, (egg) trays , containers, etc. |

Suitable Material | PLA, PP, PS, PET, PVC, EPS,CORN STARCH etc |

Max. Width of Material | 690mm |

Max. Forming Width | 650mm |

Max. Forming Length | 500mm |

Max. Forming Depth | 100mm |

Max. Cutting Speed | 10-40 Cycles/min |

Material Thickness | 0.1mm-1.5mm |

Heating Power | 52KW |

Total Power | 75KW |

Power | 380V / 50HZ (220V 60HZ) Three phase four wire |

Pressure of Water Supply | 0.2MPa |

Water Consumption | 0.3m³/h 3P Chiller |

Air Pressure | 0.6-0.8MPa |

Air Exhaust Volume | ≥1.2m³/min |

Air Compressor | 11KW |

Machine Install Size | 9200×2100×2450mm |

Machine Packing Size | 9300×2200×2600mm |

Weight | 9000KG |

Ⅴ、Machine Configuration List

Name | Brand | Place of origin |

Touch Screen | INOVANCE | China |

PLC | INOVANCE | China |

Servo Motor | INOVANCE | China |

Temperature System | INOVANCE | China |

Proximity Switch | Omron | Japan |

Power Switch | Omron | Japan |

Heating Tile | Taiqite | China |

Vacuum Pump | Rufus | China |

Relay | Schneider | France |

Circuit Breaker | Schneider | France |

Button switch | Schneider | France |

Emergency stop switch | Schneider | France |

Solenoid valve | AIRTAC | Taiwan |

Cylinder | AIRTAC | Taiwan |

Solid State Relay | Yangming | Taiwan |

Reducer | Gear | China |

Pressure Reducing Valve | AIRTAC | Taiwan |

Ⅵ、Technical Team

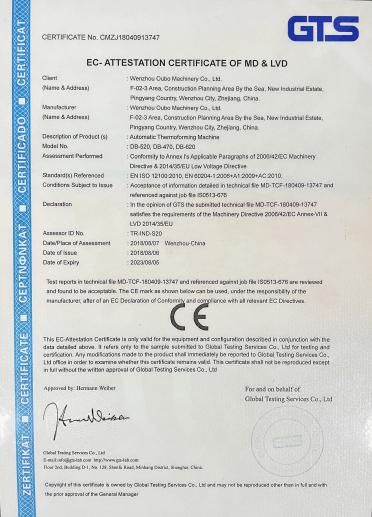

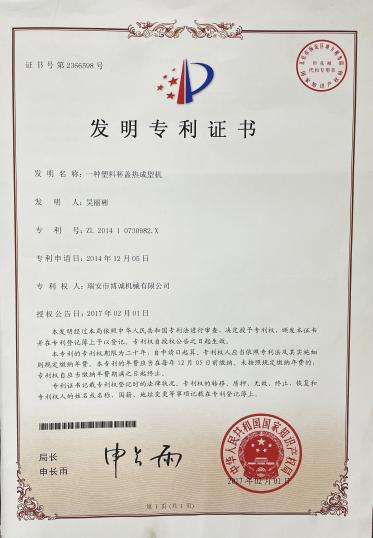

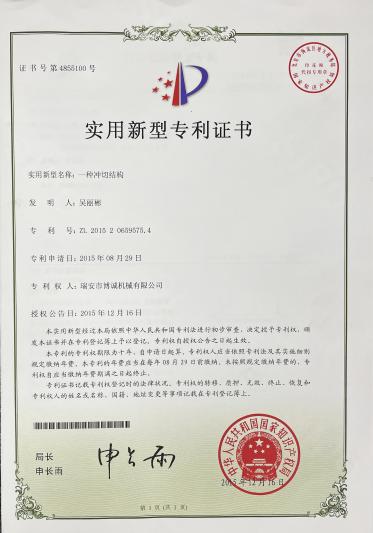

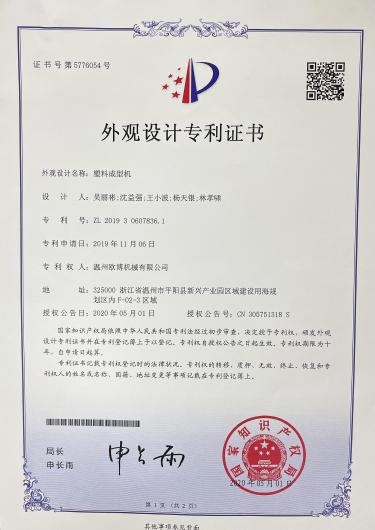

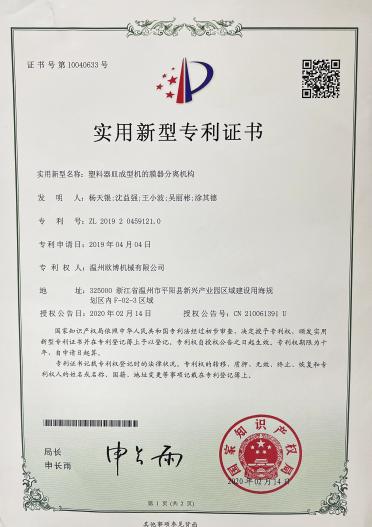

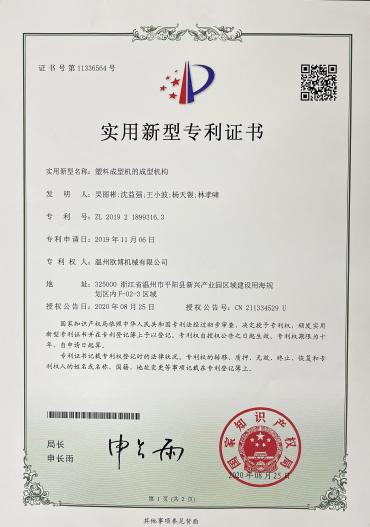

Ⅶ、Certification

|  |  |  |

|  |  |  |

Ⅷ、Applications

PLA, PVC, PET, PS,PP as raw materials, changing the mold at one machine to manufacturing lids, covers, trays, plates, boxes, food and medical trays, etc.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|